Top 5 Tips For Making Chocolate Edibles Recipes A Success

The post Top 5 Tips For Making Chocolate Edibles Recipes A Success appeared first on High Times.

If you’ve ever tried using real chocolate to make edibles, you know that it’s not easy. At Ecole Chocolat, we’ve been educating students in the art and science of chocolate making since 2003. Our graduates have gone on to open some of the most successful chocolate businesses in the country and around the world. Over the years, many of our students have wanted to work with cannabis and chocolate, and they’ve told us how frustrating it can be. With legalization on the rise across many states, and in Canada next year, the demand for edibles is only going to grow. To help dispensary owners, chocolate makers adding cannabis to their product lines, home cooks or anyone who just wants to know how to make an amazing chocolate edible, we’ve created the Pakalolo Chocolatier Program.

But more about that in a minute. In the meantime, we’ve put together our top 5 tips for working with real chocolate* and cannabis.

1) Buy the tastiest real chocolate you can afford. Not all chocolate is created equal in flavor.

Just as you carefully source your cannabis, the same must be true for your chocolate. Higher quality real chocolate will give you a better tasting final product, that’s just a fact. Have a tasting party of one where you try different chocolates to find the flavor you like the best. Once you’ve found your chocolate, make sure you know the tempering specifications recommended by the chocolate supplier. Which leads us to our next tip…

2) Understand the process of tempering chocolate.

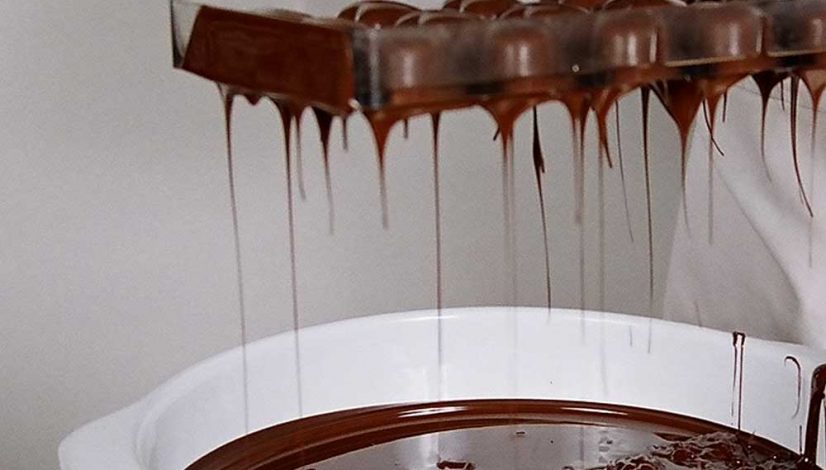

Real chocolate is a finicky ingredient to work with, and it’s very sensitive to changes in temperature. Before you try to dip, enrobe or mold anything with real chocolate, the chocolate HAS to be in temper because the cocoa butter (the only fat in real chocolate) is made up of different fatty acids. The problem is that each of these different types of fatty acids become solid at different temperatures. Tempering is like organizing individual dancers at a party into a Conga line. For chocolate, temperature and motion are the party organizers that bring all the individual dancing crystals of fatty acids together in long lines and, in the process, create a stable crystallization throughout the chocolate mass.

3) Master your chocolate tempering with practice, practice… then practice some more!

Tempering is so important, it gets two tips! There are different ways to temper chocolate, the most common are tabling (also called tabliering) and seeding. The seeding method is the easiest, where, in simplest terms, grated tempered chocolate is added to melted chocolate until the whole mass reaches your desired temperature. Once your chocolate is in temper, you have to keep it moving to make sure that it stays that way. Do frequent temper checks as you are working with it. See below for simple tempering instructions.

4) You can’t just throw some cannabis in a chocolate recipe & hope for the best

It may seem as simple as infusing some cannabis into some butter and going from there, but consumers are looking for a reliable, quality product with amazing flavor and texture. Both chocolate and cannabis come with their own distinct flavor profiles, so developing recipes and testing them repeatedly to ensure that these flavors work well together is very important. With the explosion of bean-to-bar chocolate makers in the U.S. alone, there are so many options available. Chocolate made from beans grown in different parts of the world have different flavor profiles—some are fruity, some are nutty, some are floral, and the list goes on. We strongly suggest you taste and use all of that flavor diversity.

5) Chocolate edibles are easy to accurately and consistently dose.

The great news is that chocolate edibles are a great fit for accurate dosing as opposed to some other products. Consumers are accustomed to buying chocolate bars that break into little squares. Boxed confections and bonbons traditionally come in tiny, one-bite servings. Your job is to make sure the cannabis ingredients are mixed thoroughly into the chocolate or filling mass and that the same exact amount is deposited, cut or piped into each edible form. Then, after you produce your first batch of edibles, you’ll need to test them to make sure the levels of THC and/or CBD are identical in each square or bonbon. This ensures that you are reliably dosing your products, which you can then be responsibly labeled so that consumers (or you) know exactly what type of cannabis and how much they are consuming per serving of chocolate.

We want you to be able to make the best chocolate edibles possible and hope these tips really help. Here is an abbreviated lesson on chocolate tempering by seeding from our Pakalolo Chocolatier Program. Have fun, don’t worry, it’s chocolate after all!

The Chocolate Seeding Process

Note: For best results, the ideal temperature of the kitchen should be approximately 68°F (20°C).

Step 1: To melt all fatty acid crystals, heat to 104 – 115°F (40 – 46°C).

In this example, we are using metric measurements only to make the ratio easier to understand.

Have about 1.5 kilo of chocolate on hand that has never been melted. In this process, you must use TEMPERED chocolate as your ‘seed.’ Untempered chocolate will not work as the seed since it doesn’t contain Form V crystals (we go into all that science in the program).

Weigh out the amount of real chocolate you want to temper. In our example, we are using 1 kilo real chocolate to be tempered.

We strongly suggest you don’t work with less than 1 kilo (2.2 lbs) of chocolate. Tempering tiny amounts of chocolate isn’t easy. You won’t waste any extra chocolate by tempering more than you need, as the leftover chocolate can be poured out onto parchment paper to cool, harden and be used again.

If your chocolate is not in wafer or button form, chop into chunks. Place in a bowl.

Then prepare your extra ‘seed’ chocolate and set aside in another bowl:

Determine what amount of chocolate would be 20 percent of the mass of chocolate you are planning on tempering. In our example where you are tempering 1000 grams (1 kilo), 20 percent seed would equal 200 grams.

Weigh out that 200 gram amount to use as seed. If not in wafer or button form, grate into small bits. Set aside.

You will now have two bowls of chocolate 1) 1000 grams to melt PLUS 2) an extra 200 grams to use as seed.

Melt the 1000 grams of chopped chocolate hunks or wafers using either the microwave (on 50 percent power) or a double boiler (bain-marie) over hot but not simmering or boiling water.

Temperature Check: Using a thermometer, check that the temperature of the 1 kilo melted chocolate is now between 104 – 115°F (40 – 46°C). Milk and white chocolates should only be heated to the lowest range.

Step 2: Add seed crystals to achieve temper

Remove the bowl of melted chocolate from either the microwave or the bain-marie, and stir to cool it slightly. Add your seed chocolate to the melted chocolate all at once.

Stir in the seeding chocolate bits continuously until the desired temperature is reached and they have dissolved completely. Your chocolate should now be tempered.

Temperature Check: Using a thermometer, check that the temperature of the dark chocolate is now between 88 – 90°F (31 – 32°C). Milk and white chocolate should only be 84 – 86°F (29 – 30°C). Make sure you heat the chocolate slightly if it has gone below the recommended temperatures.

Important Note: Continue to stir the tempered chocolate and check the temperature while you’re using it for enrobing or molding. Why? As chocolate is a poor conductor of heat, you need to keep those cocoa butter crystals moving to maintain temperature and keep them from solidifying.

Want to learn more? Our Pakalolo Chocolatier Program can teach you the knowledge and skills you need to know about working with fine chocolate to create amazing chocolate edibles. We cover everything from fundamental chocolate skills like tempering, dipping and molding, to modern decorating techniques, to specific knowledge about cannabis and chocolate recipe development and proper dosing methods. Visit our website www.chocolatepakalolo.com to register for our next session!

*What do we mean when we say real chocolate? We are talking about chocolate that is made with cocoa mass, sugar, and maybe some added cocoa butter and/or lecithin and that’s it. If your chocolate contains any other type of oil, or a list of ingredients you can’t pronounce, chances are it’s not real chocolate, but candy.

The post Top 5 Tips For Making Chocolate Edibles Recipes A Success appeared first on High Times.