Inside sofresh farms

The post Inside sofresh farms appeared first on High Times.

Oregon tokers are spoiled. It’s not an exaggeration to say that you can’t even give away shitty weed here. Bud that would trip everyone’s trigger in another state doesn’t even disarm the safety here. And sofresh farms’ products, with buds as dank as they get, are miles ahead of those of the state’s average grower. The farm has the best genetics, and its growers know how to maximize each strain’s potential. If you want the best pot products on the market, sofresh is the call. So sit back, roll a joint and come along on a trip through an award-winning Oregon farm.

Driving up to sofresh farms is a little underwhelming. A large fence keeps the premises out of sight from prying eyes. Once inside, though, it looks like a standard farm, not unlike one you’d expect to see elsewhere in rural America. But, of course, the cultivated plants here are anything but average. The man behind the grow is Tyson Haworth, whose bond with the plants he cares for is palpable. Haworth’s passion for growing is infectious, and everyone around him feeds off his enthusiasm. It’s hard not to get caught up in his passion when he talks about growing cannabis, and his products are considered by many to be the best of the best.

Although many growers focus on hydroponic solutions using synthetic nutrients, Haworth prefers 100 percent organic techniques. His farm has an outdoor grow area alongside a large greenhouse and several indoor growrooms. Everything is cultivated in naturally amended soil using proven organic methods. In fact, sofresh does more than just claim its products are organic; the farm has literally passed the test.

Everything sofresh farms grows is Clean Green Certified—a program that regulates cannabis products to certify they’re grown organically. Generally speaking, organic growing methods work in harmony with Mother Nature. But sofresh farms takes this organic approach to a whole new level. However, even though a perfect organic environment ensures the best possible results from a given genotype, it you don’t start with the right genetics it’s all a waste of time.

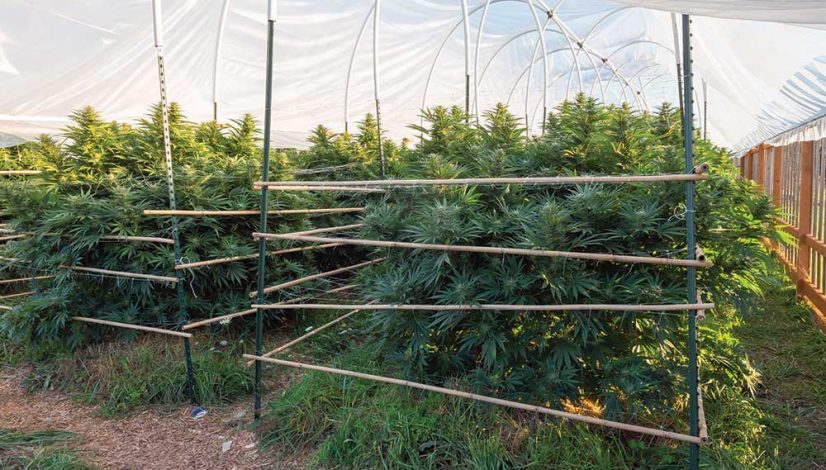

Plants maturing in a greenhouse at sofresh farms. (Photo by StinkBud/High Times)

And Haworth starts with excellent genetics—some of the best in the world. He acknowledges that growing the right strains is crucial to the foundation of any grow, and he’s always on the hunt for outstanding genetics. Selection is crucial to sofresh’s customers, so the company always keeps a couple dozen strains running. Additionally, sofresh makes sure that a few of their most popular varieties are always on hand—but even some of the farm’s most legendary strains sell out quickly.

At sofresh farms, Haworth doesn’t run mother plants. He prefers to take his clones from vegetative plants instead. That way he can run a large selection of strains without having to waste valuable space and resources keeping the mother plants alive. In his experience, he hasn’t had any issues with genetic drift using this technique. In fact, Haworth claims that you can take a plant that looks like it’s been experiencing genetic drift and place it in a healthy environment, and the plant will take off like it was a brand-new seedling.

Haworth feels that clones root better if you cut them right after the first week of flowering, as the plants are already in a transition phase and they tend to root more easily. He uses a hybrid cloning technique that utilizes a root plug inside a traditional aeroponic cloner. He takes cuttings from the healthiest plants, dips them in rooting gel and places them into the plugs.

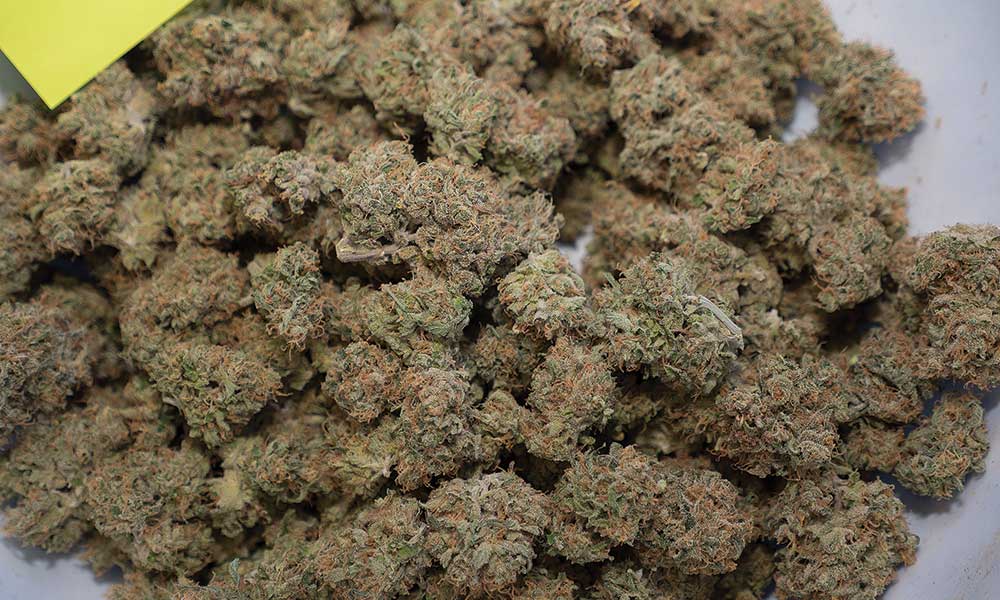

Buds are cured at the perfect temperature and humidity. (Photo by StinkBud/High Times)

Haworth takes large cuttings, looking for fresh, green stems with no woody growth, and he uses a razor blade to make a clean, sterile cut. The clone room is kept very humid with a large humidifier, and the cuttings usually take seven to 14 days to root. Haworth prefers fluorescent lights for clones, as they promote vegetative growth and are mild on the plants. He explains that too much light can cause the plants to wilt: “You want just enough light to promote root growth without killing the plants—we want roots, not leaves.”

After the clones pop roots, they are moved into either 1- or 3-gallon pots, depending on the genetics. Haworth prefers to use smart pots for the vegetative stage of growth. He explains that smart pots help prevent transplant shock, which plants can experience for up to a week. Smart pots can practically eliminate this, and they also allow roots to breathe more easily and have the added benefit of air-pruning the roots.

At sofresh farms, the veg plants are kept in a greenhouse with supplemental lighting providing 18 hours of light. A combination of sunlight and artificial light allows the plants to “harden” and acclimate to the sunlight. Plants can get sunburnt just like us humans, and hardening the plants is similar to giving the plants a base tan. Then, after they’re acclimated to the bright lights or sunshine, the plants are moved into the flower stage—and that’s where the real magic begins.

The sofresh indoor growing area uses a closed-loop system with no-till raised beds. Haworth prefers to use high-pressure sodium (HPS) lights, but he’s always testing new systems and reflectors. Lately, he’s been researching three different light configurations to find the most efficient system possible. Haworth’s also been measuring the differences between a closed-loop system with supplemental CO2 and a hybrid system with fresh-air ventilation. In the winter, sofresh farms brings in cool air from the outside instead of using air-conditioning. This not only uses less power, but it also replenishes CO2 naturally. But during the hot summer months, sofresh farms runs air-conditioning to keep the temperature below 85°F. This keeps terpene loss to a minimum, which helps with fragrance intensity.

The raised-soil beds that sofresh farms uses stand about 2 feet high and comprise a mixture of peat moss, pearlite, worm castings and compost, as well as other common additives, with the ultimate goal of creating synergy between the plants and soil. Haworth creates a “living soil” by building an environment that is perfect for both beneficial bacteria and the cannabis crop. He starts by inoculating the plants early in the vegetative stage and then carries it through to flower. Haworth brews his own tea, but instead of adding bacteria to the brew and letting it ferment, he adds the compost extract directly to the soil and lets the beneficial bacteria break it down. Basically, he’s feeding the bacteria that help his plants. This makes the beneficial bacteria very healthy and happy, and they respond by breaking down the nutrients the plants need in order to flourish. This symbiotic relationship is a key element to any successful organic grow.

If you’ve ever hiked down a dirt trail, you already know how soil gets compacted by people walking on it. Haworth says that one of the worst things that can happen to soil is having it compacted so much that all the minute air pockets are destroyed. Those small spaces not only store oxygen, but they also act as water reservoirs and allow roots a place to grow. That’s why Haworth built wooden walkways above his flower beds, which help keep the soil fluffier than grandma’s pancakes and the buds as sweet as syrup.

Environmental control is essential to success. (Photo by StinkBud/High Times)

Have you ever been out hiking when your feet get soaking wet, and then when you take off your shoes your feet look like a couple of raisins from hell? Plants don’t like their feet—their roots—getting that saturated with water any more than you do. That’s why keeping the soil’s moisture content in perfect balance is so important. Anyone can throw some water on the ground, but it’s a lot more complicated than that. Haworth is the master of moisture balance. How does he do it?

First, Haworth uses a thin layer of straw mulch on top of the soil to keep moisture from escaping while still allowing the soil underneath to breathe. He’ll push aside the straw and stick his hand in wrist-deep, pulling out a clump of deep black soil that he compacts in his hands, making a small dirt clod. He explains that if the soil is too dry, the dirt clod won’t hold together. The clod should break apart easily. If it doesn’t, there’s too much moisture. This simple technique allows Haworth to keep the soil at exactly the right balance.

Haworth feels that there are benefits to growing plants together in the same bed. They’re able to share microbes and worms, and they also communicate with one another. Plants need room to grow both above- and belowground. Haworth accomplishes this by preparing the soil deep below the raised beds so that the plants’ roots grow freely. Growing large plants in small pots is like trying to squeeze into last year’s swimsuit. You could pull it off, but no one is going to be happy about it.

Whether you feed your plants synthetic or organic nutrients, the goal is usually the same: tasty bud! Haworth believes that an organic approach is best for both his plants and his customers. So not only does he hunt down the finest organic ingredients money can buy, he also makes his own.

At sofresh farms, they take the leaves and stems from the thinning and trimming process and put them into large 55-gallon containers. Water and lactic-acid bacteria are added to the mix and allowed to stew until the concoction smells like an old gym locker. When the mix stops bubbling, the lid is removed and the alcohol is allowed to evaporate. What’s left is the perfect blend of nutrients in the perfect ratio. During the flower stage, Haworth adds more stems and less leaves. This blend, combined with naturally amended soil, makes for beautiful and healthy plants.

Haworth’s sofresh farms takes organic pest control to a whole new level. It’s called “integrated pest management,” or IPM. Under a canopy of a cannabis growth, other plants such as grass and clover are planted. The purpose in growing cover plants is to provide an environment that is friendly to predatory insects, and it also creates a symbiotic relationship with the cannabis plants. Haworth explains the different types of plants he uses.

“Trap plants” attract the bad bugs, and basically act as an all-you-can-eat buffet, featuring all kinds of yummy stuff for these bad bugs to eat. Haworth closely monitors the trap plants for any signs of pests that could mean an infestation for his crop.

In addition to trap plants, the farm also uses “deterrent plants” that help keep pests away. Plants like rosemary, mint and peppers repel problem insects and mites. These deterrent plants are like growroom bouncers, keeping away any unwanted guests. Haworth views trap plants and deterrent plants as the first line of defense for the grow. But he also uses other methods to keep pests at bay.

Flowers form on budding branches. (Photo by StinkBud/High Times)

Not every type of bug is bad for your plants. There are many types of predators that eat the insects that eat your plants. Most likely you’re familiar with many of the common types of predator insects, such as ladybugs and praying mantises, but you may be less familiar with nematodes or fungi. When these little fellas invade the host’s body, they eat it from the inside out, and then use it to eliminate other pests. This natural approach to pest management helps eliminate pesticide use and creates a healthier environment.

The last line of defense against garden pests is the use of organic sprays such as soaps and neem, cinnamon, lemongrass and other types of oils. These sprays either suffocate the pests or make the plant taste bad to them. Neem oil has been used for centuries and controls virtually every type of pest, and a small amount of it is all it takes to make the bugs dine elsewhere. Haworth also uses PFR-97, an organic solution that contains a naturally occurring fungus which kills many of the bad bugs on leaves and in the soil.

There’s a large greenhouse at sofresh farms in which budding plants are spread out as far as the eye can see. Some of the greenery resembles mini-skyscrapers, while other verdure grows low and dense. There are three levels of netting laid out into 6-foot x 6-foot grids, each with a 1,000-watt light over it. Haworth explains that the netting helps train the plants to create a solid canopy of dense buds roughly two feet thick.

Haworth inspects the plant’s trichomes to determine the correct harvest time, looking for the heads to be mostly cloudy with some turning amber. He doesn’t like to wait too long for harvest, as a plant’s terpenes can start to degrade. Harvest time is strain-dependent, so over the course of a month, plants will be pulled and processed.

There are multiple drying rooms set up to accommodate sofresh farms’ various crops. Some hold large, untrimmed outdoor plants, while others contain rows of buds hanging from the ceiling. These are from the indoor grow and already have their fan leaves removed. It looks like all it would take is a couple of good snips for these buds to be ready to enjoy.

Haworth starts the buds out at a fairly low 40 percent humidity level and raises it over a few weeks to 50 percent, with the ultimate goal of hitting 60 percent. He explains that anything above that adds moisture to the bud, and anything below that dries it out.

When the buds reach the perfect level of dryness, they are hand-trimmed by some of the best trimmers in the world, who cut a staggering amount of marijuana every day. The buds are handled very carefully; workers avoid touching the pot with their bare hands and only use the tips of their scissors. Every kickstand and crow’s foot is clipped with only frosty goodness left behind. Every flower is trimmed to the perfect size—not too big, not too small.

Hanging branches to dry preserves delicate trichome glands. (Photo by StinkBud/High Times)

After the nugs have been trimmed, they’re placed in large totes to cure. This process takes from a few weeks to a couple of months’ time, depending on the strain. The totes aren’t airtight, allowing the buds to breathe and slowly cure to perfection. Cure time can make a huge difference in how the finished cannabis smokes.

After spending time in the large totes, the pot is transferred into gallon jars. Haworth pulls a bud out of one and holds it up, bending the stem until, at a certain point, it snaps. That’s exactly what he’s looking for. If the stem bends but doesn’t break, it’s still too wet. If the stem snaps right away, the bud’s too dry. Haworth views the moisture content of the flowers as crucially important to the quality of the final results.

The product from sofresh farms is legendary in Oregon, and for a good reason—it’s the best of the best. Sure, the farm has won many awards, but what really sets it apart is its staff. After spending time with the sofresh crew, I can’t help but feel amazed at their vast knowledge of growing technique. Plants come and go, and all those beautiful buds are just a hit away from disappearing in a puff of smoke. The farmer, not the plants, makes the farm, and Tyson Haworth is without equal. The next time you’re in Oregon, stop by the nearest pot shop and ask for sofresh farms.

The post Inside sofresh farms appeared first on High Times.